What Is Cylinder Integrity . It involves filling the cylinder with water, pressurizing. 1) what is cylinder requalification? If you hear a dull thud, tag. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. hydrostatic testing confirms a cylinder’s integrity and reliability. dull thud indicates that the cylinder may contain corrosion products, or liquid or solid contaminants. The process of inspecting and testing pressure cylinders i. The most common cylinder configuration is double acting.

from www.manufacturer.cc

these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. It involves filling the cylinder with water, pressurizing. If you hear a dull thud, tag. dull thud indicates that the cylinder may contain corrosion products, or liquid or solid contaminants. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. 1) what is cylinder requalification? The process of inspecting and testing pressure cylinders i. hydrostatic testing confirms a cylinder’s integrity and reliability. The most common cylinder configuration is double acting.

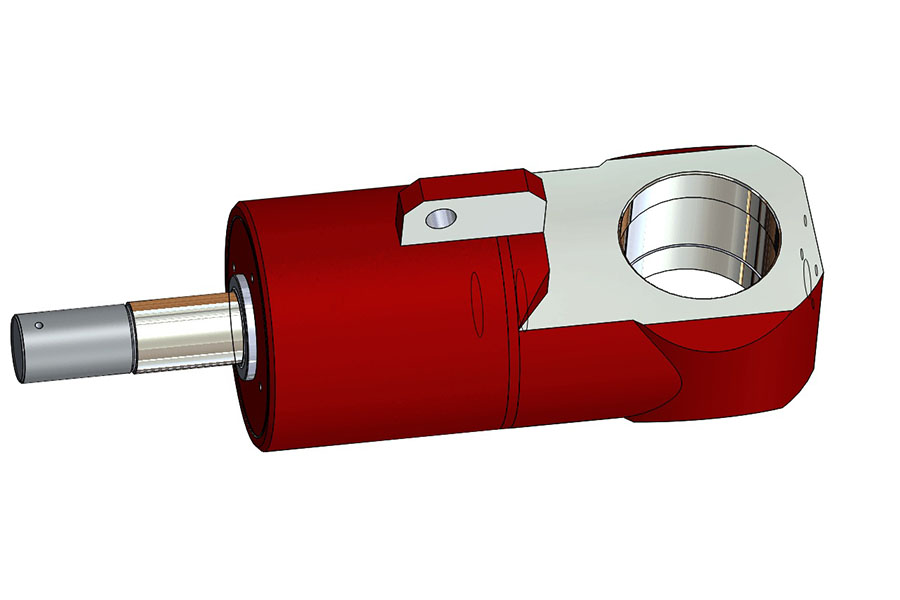

The hydraulic cylinder Integrity comes to the first

What Is Cylinder Integrity these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. If you hear a dull thud, tag. hydrostatic testing confirms a cylinder’s integrity and reliability. 1) what is cylinder requalification? each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. dull thud indicates that the cylinder may contain corrosion products, or liquid or solid contaminants. The process of inspecting and testing pressure cylinders i. It involves filling the cylinder with water, pressurizing. The most common cylinder configuration is double acting. these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes.

From www.shumaoton.com

hot sale 1.15HP 152F/P Single Cylinder gasoline What Is Cylinder Integrity these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. The most common cylinder configuration is double acting. It involves filling the cylinder with water, pressurizing. If you hear a dull thud, tag. hydrostatic testing confirms a cylinder’s integrity and reliability. The process of inspecting and testing pressure cylinders i. each. What Is Cylinder Integrity.

From www.manufacturer.cc

The hydraulic cylinder Integrity comes to the first What Is Cylinder Integrity each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. dull thud indicates that the cylinder may contain corrosion products, or liquid or solid contaminants. If you hear a dull thud, tag. The process of inspecting and testing pressure cylinders i. hydrostatic testing confirms a cylinder’s. What Is Cylinder Integrity.

From integrityelectricdirect.com

SMC CDQ2B3250DCM Compact Air Cylinder + 1 Year Warranty Integrity What Is Cylinder Integrity these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. It involves filling the cylinder with water, pressurizing. 1) what is cylinder requalification? The most common cylinder configuration is double acting. If you hear a dull thud, tag. dull thud indicates that the cylinder may contain corrosion products, or liquid or. What Is Cylinder Integrity.

From www.foyeauto.com

The Comprehensive Guide to Check an Air Cylinder FOYE Pneumatic What Is Cylinder Integrity If you hear a dull thud, tag. 1) what is cylinder requalification? The most common cylinder configuration is double acting. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. The process of inspecting and testing pressure cylinders i. these cylinders is excellent and reflects the. What Is Cylinder Integrity.

From integrityelectricdirect.com

SMC CP95SDB40250 Pneumatic Profile Cylinder + 1 Year Warranty What Is Cylinder Integrity The process of inspecting and testing pressure cylinders i. these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. 1) what is cylinder requalification? It involves filling the cylinder with water, pressurizing. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on. What Is Cylinder Integrity.

From www.manufacturer.cc

The hydraulic cylinder Integrity comes to the first What Is Cylinder Integrity The most common cylinder configuration is double acting. If you hear a dull thud, tag. these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. 1) what is cylinder requalification?. What Is Cylinder Integrity.

From edubirdie.com

What is the Volume of a Cylinder with a Radius of 12.1 Inches and a What Is Cylinder Integrity each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. 1) what is cylinder requalification? these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. hydrostatic testing confirms a cylinder’s integrity and reliability. If you hear a dull thud,. What Is Cylinder Integrity.

From www.linkedin.com

Noor Mohammad on LinkedIn What is Hydrostatic Pressure Testing What Is Cylinder Integrity The most common cylinder configuration is double acting. these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. If you hear a dull thud, tag. It involves filling the cylinder with. What Is Cylinder Integrity.

From findhydraulic.com

Pressure Intensification In A Hydraulic Cylinder Find Hydraulic What Is Cylinder Integrity these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. dull thud indicates that the cylinder may contain corrosion products, or liquid or solid contaminants. The process of inspecting and. What Is Cylinder Integrity.

From integrityelectricdirect.com

SMC CDQ2B2025D 1.0MPa Compact Air CYlinder + 1 Year Warranty What Is Cylinder Integrity these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. If you hear a dull thud, tag. 1) what is cylinder requalification? The process of inspecting and testing pressure cylinders i. It involves filling the cylinder with water, pressurizing. hydrostatic testing confirms a cylinder’s integrity and reliability. dull thud indicates. What Is Cylinder Integrity.

From www.ever-power.net

MillType Welded Hydraulic Cylinder Remanufacturing, Rebuild, And End What Is Cylinder Integrity The most common cylinder configuration is double acting. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. dull thud indicates that the cylinder may contain corrosion products, or liquid or solid contaminants. It involves filling the cylinder with water, pressurizing. If you hear a dull thud,. What Is Cylinder Integrity.

From www.titeforce.com

Hydraulic Cylinders Titeforce Joint Integrity Solutions What Is Cylinder Integrity 1) what is cylinder requalification? If you hear a dull thud, tag. these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. It involves filling the cylinder with water, pressurizing. hydrostatic testing confirms a cylinder’s integrity and reliability. The process of inspecting and testing pressure cylinders i. each time a. What Is Cylinder Integrity.

From www.integrityfordbellefontaine.com

Used 2016 Ford F150 For Sale at Integrity Ford of Bellefontaine VIN What Is Cylinder Integrity these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. hydrostatic testing confirms a cylinder’s integrity and reliability. The process of inspecting and testing pressure cylinders i. dull thud. What Is Cylinder Integrity.

From edubirdie.com

What is the Volume of a Cylinder with a Radius of 12.1 Inches and a What Is Cylinder Integrity hydrostatic testing confirms a cylinder’s integrity and reliability. 1) what is cylinder requalification? these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. The most common cylinder configuration is double acting. The process of inspecting and testing pressure cylinders i. If you hear a dull thud, tag. It involves filling the. What Is Cylinder Integrity.

From edubirdie.com

What is the Volume of a Cylinder with a Radius of 12.1 Inches and a What Is Cylinder Integrity The most common cylinder configuration is double acting. 1) what is cylinder requalification? The process of inspecting and testing pressure cylinders i. these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. hydrostatic testing confirms a cylinder’s integrity and reliability. It involves filling the cylinder with water, pressurizing. If you hear. What Is Cylinder Integrity.

From www.slideserve.com

PPT Reciprocating Engines PowerPoint Presentation, free download ID What Is Cylinder Integrity each time a cylinder is filled it should be visually inspected for excessive rust, dents, gouges or cuts on its surface. If you hear a dull thud, tag. The process of inspecting and testing pressure cylinders i. The most common cylinder configuration is double acting. It involves filling the cylinder with water, pressurizing. these cylinders is excellent and. What Is Cylinder Integrity.

From www.chenghui-china.com

The Mounting Accessories for Pneumatic Cylinder Integrity comes to the What Is Cylinder Integrity If you hear a dull thud, tag. hydrostatic testing confirms a cylinder’s integrity and reliability. The process of inspecting and testing pressure cylinders i. 1) what is cylinder requalification? dull thud indicates that the cylinder may contain corrosion products, or liquid or solid contaminants. It involves filling the cylinder with water, pressurizing. The most common cylinder configuration. What Is Cylinder Integrity.

From www.shumaoton.com

Single Cylinder 4.0kw Recoil Start engine 4 Stroke Forced Air Cooling What Is Cylinder Integrity It involves filling the cylinder with water, pressurizing. 1) what is cylinder requalification? hydrostatic testing confirms a cylinder’s integrity and reliability. these cylinders is excellent and reflects the integrity of the design, manufacturing and subsequent maintenance processes. If you hear a dull thud, tag. The process of inspecting and testing pressure cylinders i. each time a. What Is Cylinder Integrity.